LARGE FLOW COMMON USE TYPE 2 WAY SOLENOID VALVES1. High performance, high flow, with little electric power required.

2. Water proof coil available when required. Normally closed solenoid valve, connection size : 1/2"~2-1/2" (Pipe). Flange connection size : 1/2"~6" For Fluid : Water, Air, Hot Water, Steam, Oil.

|

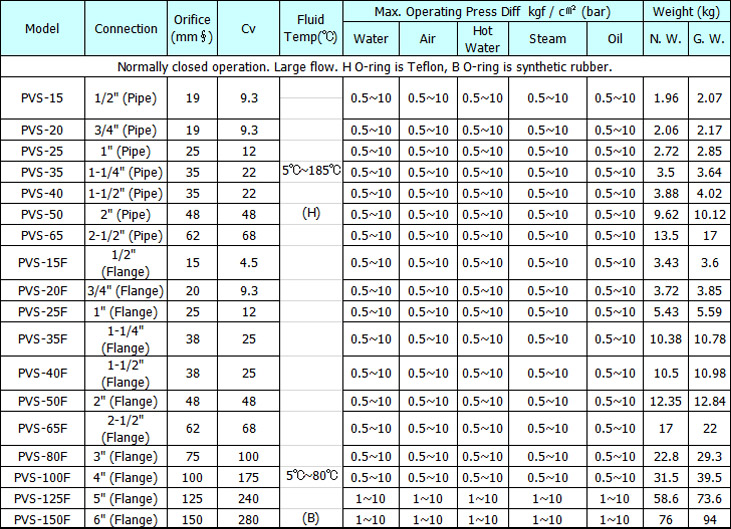

Specifications1. Bodies of valves with mouths which are 1-1/4" or less are bronze; bodies of those with mouths 2" or greater are cast iron.

2. Horizontal piping and double acting pistons 3. Standard voltage: AC 110V / 220V (50 / 60Hz). Other voltage of AC/DC available when required. Voltage is white ±10% differential. |

Items of Attention1. Not for fluid of viscosity over 50 cst.

2. Not for liquid that solidifies when cool. 3. Not for corrosive fluid. 4. This type of solenoid valve has come no leak. 5. This type can be pipe-fitted on needed direction. 6. A steam strainer or filter has to be installed one meter away from the solenoid valve. And the pipes must be washed neat and clean before fitting. 7. A strainer has to be installed in the front of solenoid valve, that is best for long life. |

Specifications |

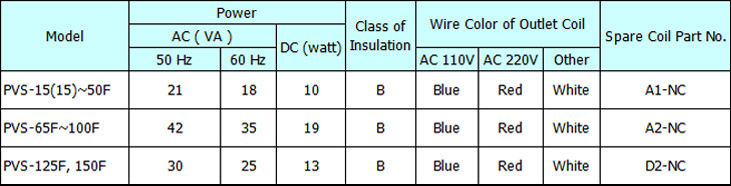

Electrical Information |

Wei-En Electric Machinery Co. Ltd. - We are a Taiwan manufacturer of solenoids, valves, actuators and accessories

Our solenoids and actuators have certifications in CE, cUL, CSA, ISO 9001, IP67